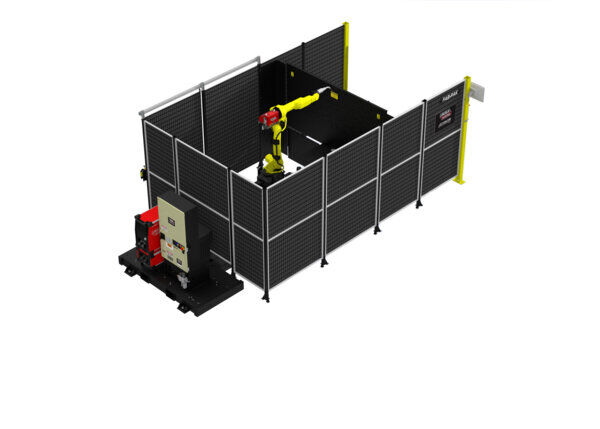

Lincoln Electric Fab-Pak® XFT Robotic Welding Cell with Fanuc Robot

Description

Ideal for small- to medium-sized parts that don’t need reorientation

What’s Included

- Power Wave® R450 power source

- AutoDrive® AD2504 wire feeder

- Magnum® PRO robotic torch

- Power Ream® II torch maintenance unit

- Integration-Ready Refurbished Fanuc ArcMate welding robot

- Robot basic software package

- Wire mesh panels with weld curtains

- Push button control

Details

Designed for the high-mix, low volume manufacturing industry, the Fab-Pak® family of robotic welding systems provides businesses with a wide range of manufacturing capabilities and system flexibility. The Fab-Pak XFT standard robotic welding system provides increased throughput efficiency, accuracy, and repeatability.

Features

- Servo-driven turntable positioner

- 180° rotating work area

- Increases throughput efficiency, accuracy, and repeatability

- ANSI/RIA safety compliant

Options Available:

- Water-cooled torch

- LaserTouch (requires water-cooled torch)

- TouchSense

- Thru Arc Seam Tracking

- Touchscreen HMI

- Fume filtration

- Tooling tables and beams

- Virtual or in-person training

Specifications

Product #

AD2505

Model Name

XFT 3000mm

System Type

Indexing Fixed Table

Number of Work Zones

2

Industry/Application

High-mix, low-volume manufacturing

Overall Footprint Width in (mm)

170 (4321), 229 (5815), 258 (6560)

Overall Footprint Depth in (mm)

77 (1957), 117 (2975), 141 (3575)

Sweep in (mm)

NA

Span in (mm)

N/A

Turntable Diameter in (mm)

67 (1700), 89 (2250), 118 (3000)

Payload Per Zone lb (kg)

770 (350), 1100 (500), 2200 (1000)

Panel Type

Wire Mesh/Curtain

Crane Access

Yes

Roll Up Door

No

Pushbutton Control

Yes

HMI Control

Optional

Power Distribution

Optional

Robot Programming Training Included

Yes

ANSI/RIA Compliant

Yes

Sensor Protected Work Zones

Yes

Sensor Interlocked Access Points

Yes

Fume Extraction Equipment

Optional

Multi-Robot Configurations

Optional

Crown Mounted Robot

No

Robotic Torch Cleaning Station

Optional

Weld Gas Distribution Station

No

Weld Gas Flow Monitor

No

Pneumatic Distribution Station

No

Zero Friction Wire Delivery

No

Wire Detect Sensors

No

Customization Available

No