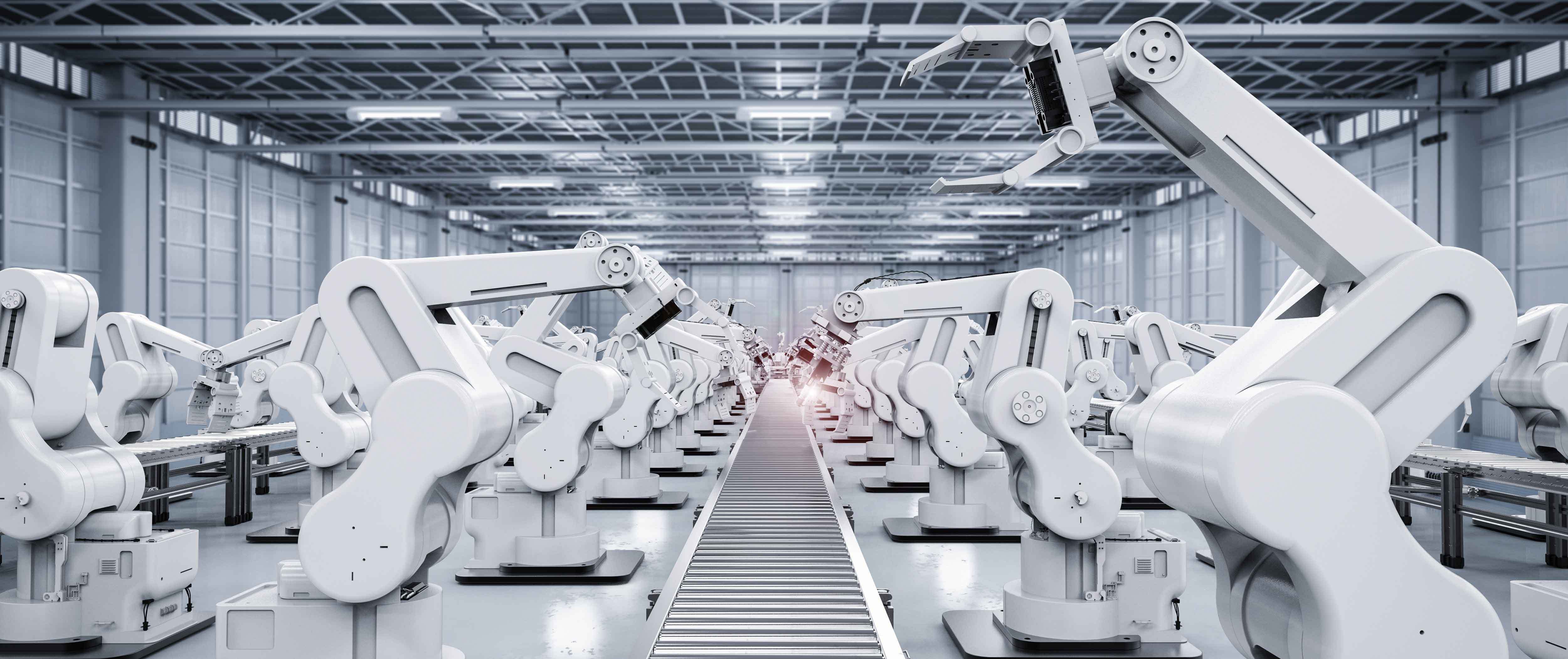

Most Popular Industrial Robotic Applications for 2021 and Projections

Jun 1, 2021

Explore the most popular application trends of 2021 and what to expect in the future.

Automation solution providers encountered a major shift in the market in 2021. The covid-19 pandemic created a demand for automation in various business sectors, including those outside industrial manufacturing. Statistics published by the Association for Advancing Automation (A3) show that North American robotic sales increased by 3.5% in 2020 and are continuing to see positive growth. The pandemic brought many challenges to businesses like supply shortages, new safety precautions, and a major employment gap. Companies had to redesign business models and supply chain management to develop lean production processes with higher output to overcome these challenges. With many products facing supply shortages, industries such as manufacturing, life science, food processing, retail, and delivery/fulfillment have looked to automation as the solution. This has led to the automation of new applications and advancements to common applications.

Sorting Applications

Sorting and organizing technology have seen a sharp increase in sales due to the medical and food supply shortages resulting from the Covid-19 pandemic. The sudden changes in consumer buying habits increased the value of automation for companies across industries. Automation for sorting applications offers a long-term solution for labor shortages, social distancing requirements, and supply chain overhaul for businesses. The increased robotic market revenue from sorting applications brought forth complex and innovative solutions such as vision-based sorting and cleanroom robotics. Companies are using vision and machine learning with industrial robots to execute sorting tasks that involve vision-based decisions. Robotic companies released cleanroom robots for environments requiring sanitation tasks such as preparing syringes for coating, placing pills into bottles and capping them, and handling food packaging. Sorting robots continue to gain visibility and expand capabilities for significant improvements to production operations and product output.

Quality Inspection Applications

Quality control is used to eliminate defects and ensure customers receive products that meet their expectations. This application is pushed across all manufacturing industries to improve product quality. Cutting-edge vision technology has opened the door for automation to take over and improve this task. Operations can now implement quality control in new areas, eliminating defects that are not visible to the naked eye. An example of this technology is spectral imaging which detects color spectrums that human workers cannot perceive. These cameras are used in fresh-produce inspections to detect areas that are spoiled or foreign objects within the goods. Errors resulting from inadequate quality inspections can be dangerous, costly, and detrimental to a company’s image. Vision technology gives an extra layer of security in ensuring all products leaving production are of the highest quality to consumers.

Collaborative Applications

Collaborative robots have made a come-back after two years of underperformance due to factory shutdowns during the Covid-19 pandemic. As discussed previously in the sorting application section, the recovery phase for companies requires a quick and efficient solution for supply shortages and safety restrictions. Companies are implementing collaborative technology in strategic ways to overcome employment gaps, social distancing restrictions, and the immediate need for leaner production processes. Some of the more popular uses of collaborative robots are for inspections, sorting, and packaging in collaboration with workers. Robot manufacturers, like Yaskawa, recently announced a new “Smart Series” cobot line that reduces research processes by providing investors with all the necessary accessories to guarantee fast setup. More industries are integrating cobots, manufacturing and non-manufacturing, as a quick and affordable turnkey solution.

Mobile Robot Applications

The most significant influencer of supply chain industries has been the tremendous growth of e‑commerce sales following the global pandemic. Robots are used across all parts of the supply chain, but as e‑commerce fulfillment increases, mobile robots in warehouses and distribution centers are inevitable. These robots autonomous industrial industrially change routes without human intervention and can operate collaboratively with workers to perform tasks. In addition, technologies like voice-picking provide companies with faster production time and flexibility in workflow. Voice Picking is software that gives AMRs the capability to operate by giving verbal commands to the mobile robots. Companies using voice-picking AMRs report having immediate gain in productivity and savings with annual labor costs. The notoriety of mobile robots is exploding because of the flexible task handling they provide that other automation solutions and manual labor do not.

What Are the Capabilities of Automation in the Future?

The recent surge in automation was a response to overcome supply shortages caused by COVID-19. The drastic increase in demand within such a short time frame made it difficult for suppliers to keep up without automating. Last year, in 2020, A3 reported robot orders from life science industries increased by a momentous 69% compared to the previous year. Market analysts project that life science industries, among other sectors, will continue to see more companies automating within the next few years. With more investments being put into automation, advancements will come at a quicker rate. Automation is now blending traditional industrial robots with IoT (Internet of Things) technology to create lean production processes further and collect data for the systems to improve efficiency autonomous industrial industrially. Converging these two technologies into one system that physically automates and digitally records data that can be used for machine learning and improving processes. Future automation will feature more of this blended technology, offering consumers cutting-edge automation to further enhance their supply chain process.

Related Articles

You might be also interested in:

- Featured

Latest Advancements in Material Cutting Robotics

Read about the latest technological advancements in robotic material cutting.

- Featured

Emerging 3D Vision Technologies for Industrial Robots

Learn about the emerging 3D vision technology that businesses are using for industrial robot applications.

- Featured

Most Popular Industrial Robotic Applications for 2021 and Projections

Explore the most popular application trends of 2021 and what to expect in the future.

Let's talk!

Request your quick quote today.