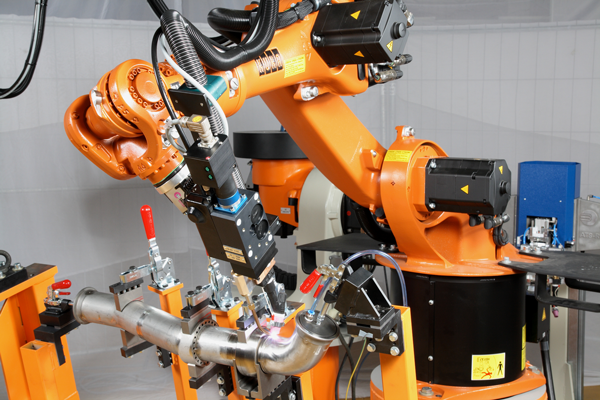

Laser cutting with KUKA Robotics

Feb 4, 2014

Using a KUKA laser cutting robot for your cutting application will help to eradicate interruptions and downtime. The safety environment is further improved as it removes human workers from the particles and metal shards that are released during the laser cutting process.

Safety is a key to any manufacturing industry. When safety is not a priority in a shop, there are more instances of downtime and production interruptions, due to sickness and injuries. When you use a KUKA laser cutting robot for your cutting application, these types of interruptions can be almost completely eradicated, which improves your safety level, while also improving the level of morale in your factory.

Any time you cut a piece of material, tiny particles surrounding the edges of the material will be released in the air. If you’re talking about food particles or biodegradable particles, that may not be a big deal. But, KUKA laser cutting robotic systems are usually used in metal plate cutting. When metal is cut, very small shards can be released into the air. If a human worker was performing the cutting application close to the work piece, those shards could be breathed into their respiratory system and cause buildup and disease over time.

Another issue that may be a problem cutting applications without the use of robots like the KUKA laser cutter is the issue of workers burning or cutting their hands during the instance of manual application. When choosing a KUKA robotic laser cutter, manufacturers are getting a system that keeps workers back away from the danger zone during operation, which keeps their body away from the heat and possible particles produced during the application process. When downtime is decreased and workers are no longer ill, morale is raised in the shop overall, which is always a good thing.

So, are you interested in these advantages for your shop? If so, you need to call Robots.com. Robots.com provides solutions from several different robotics companies, including KUKA robotics. Our staff will work with you to build the perfect laser cutting robotic system for your factory floor and application’s operation.

For more information, contact Robots.com online or at 877−762−6881.

Related Articles

You might be also interested in:

- Featured

Latest Advancements in Material Cutting Robotics

Read about the latest technological advancements in robotic material cutting.

- Featured

Emerging 3D Vision Technologies for Industrial Robots

Learn about the emerging 3D vision technology that businesses are using for industrial robot applications.

- Featured

Most Popular Industrial Robotic Applications for 2021 and Projections

Explore the most popular application trends of 2021 and what to expect in the future.

Let's talk!

Request your quick quote today.