Consistency and Reliability with Robotic Spot Welders

Mar 11, 2014

Robotic spot welding will bring consistency and reliability to your production line. Spot welding robots can be used in a wide range of applications such as automotive, aerospace, rail and defense industries. They can bring greater levels of speed and accuracy to the manufacturing process.

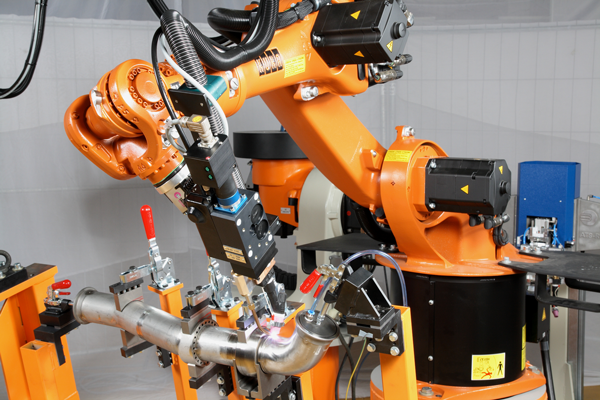

Robotic spot welding is one of the most common uses for robot welding systems today. Spot welding robots are used in several different industries, including the automotive, aerospace, rail and defense industries. Robotic spot welders are consistent and reliable, while also contributing a higher level of speed and accuracy to the application.

Spot welding is not an easy job, especially when it is performed manually. Spot welding guns are heavy and awkward, and it can be difficult for a welder to reach certain angles. With the help of robotic spot welding systems, this is no longer a problem for many manufacturers. Spot welding robotics are able to reach those difficult welding angles because of extended reach and rotation abilities.

Like many other types of applications taken over by robots, spot welding can be a dangerous application for workers. While burns are always a concern when working with an application like welding, there is also the issue of arc glare, which can damage the eyes, and welding fumes, which can cause issues for the respiratory system. An investment in a robotic spot welder will take the worker away from the dangerous area, and put them behind the robot as an operator. This also allows the worker to learn new, marketable skills. It is a win-win for the employer and the employee – increased production, decreased production interruptions and better skills.

Are you interested in possibly buying a new or refurbished robotic spot welding system? If so, Robots.com is the place to call. Robots.com provides solutions from several different robotics companies, including Fanuc, Motoman, KUKA, and ABB. Our staff will work with you to build the perfect new or used system for your application and budget.

For more information, contact Robots.com here or call us at 877−762−6881.

Related Articles

You might be also interested in:

- Featured

Latest Advancements in Material Cutting Robotics

Read about the latest technological advancements in robotic material cutting.

- Featured

Emerging 3D Vision Technologies for Industrial Robots

Learn about the emerging 3D vision technology that businesses are using for industrial robot applications.

- Featured

Most Popular Industrial Robotic Applications for 2021 and Projections

Explore the most popular application trends of 2021 and what to expect in the future.

Let's talk!

Request your quick quote today.