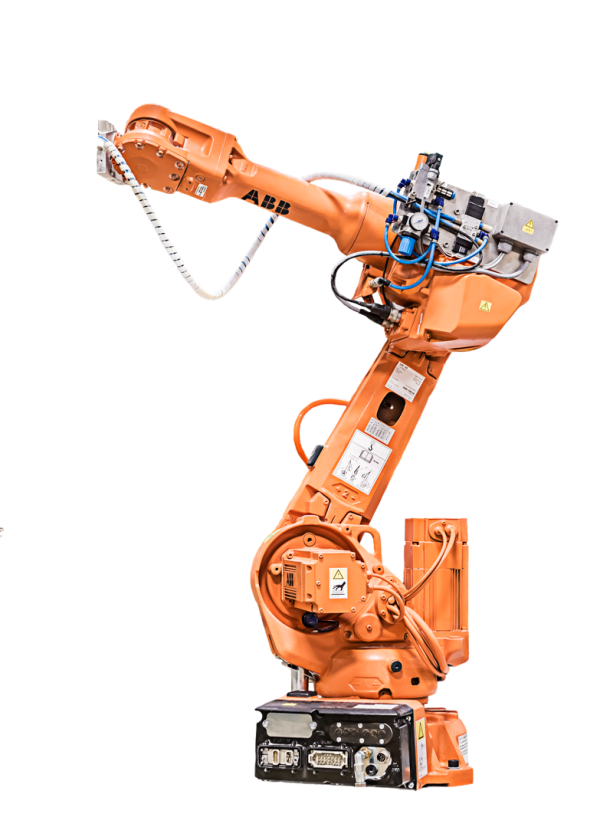

ABB IRB 2600

Arc Welding Robots, Cutting Robots, Deburring Robots, Drilling Robots, Fiberglass Cutting Robots, Grinding Robots, Laser Welding Robots, Machine Tending Robots, Material Handling Robots, Material Removal Robots, Milling Robots, Polishing Robots, Routing Robots, Sanding Robots, Spindle Robots, Meat Processing Automation Robots

Arc Welding Robots, Cutting Robots, Deburring Robots, Drilling Robots, Fiberglass Cutting Robots, Grinding Robots, Laser Welding Robots, Machine Tending Robots, Material Handling Robots, Material Removal Robots, Milling Robots, Polishing Robots, Routing Robots, Sanding Robots, Spindle Robots, Meat Processing Automation Robots

Details

The highly accurate ABB IRB 2600 increase production through high process speeds and low waste amounts. The patented ABB software, TrueMove, is used for ultimate motion control. The compact design of the IRB 2600 IRC5 cuts cycle times by up to 25%. Maximum acceleration is achieved by the new lower body weight of the arm.

With the same footprint as the IRB 4600 IRC5, significant floorspace can be used by integrating the IRB 2600. The reach of this compact arm can extend underneath the body, creating a large working envelope. This arm is available with a longer reach, higher payload, and a variety of protection packages such as FoundryPlus 2, Foundry Prime 2, and Clean room.

There are also used ABB IRB 2600 robots available through Robots.com. Each used IRB 2600 goes through a rigorous reconditioning process, bringing it back to mint condition.

Specs

Motion Speed

Motion Range

Applications

Arc Welding Robots

Cutting Robots

Deburring Robots

Drilling Robots

Fiberglass Cutting Robots

Grinding Robots

Laser Welding Robots

Machine Tending Robots

Material Handling Robots

Material Removal Robots

Milling Robots

Polishing Robots

Routing Robots

Sanding Robots

Spindle Robots

Meat Processing Automation Robots

Let's talk!

Can’t find what you are looking for?

Call specialist on +18777626881 or write a message.

- [email protected]

- Phone

- 877-762-6881

- Office

-

1216 Heil Quaker Blvd

La Vergne, TN 37086

- Socials